- Automotive Interior Molds

- GMT / Low Pressure Injection Molds

- SMC Molds

- Transbeam_Smartphone Flashlight Kit(4in1)

- Catalogue

- Product title

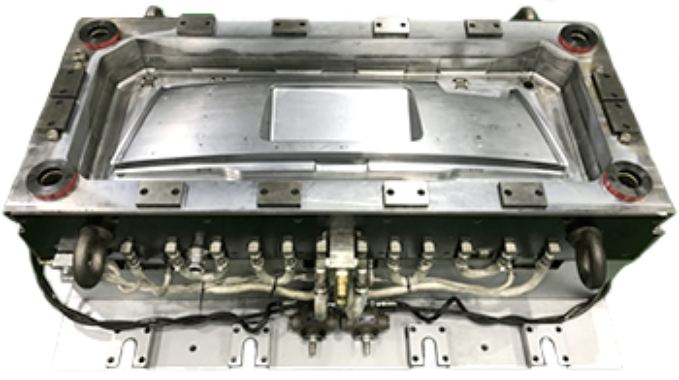

Design and manufacture the special molds for automotive interior parts and NVH parts. Types of molds include Hot forming molds, Cold forming molds, Steam forming molds, Foaming molds, Vacuum forming molds, and Insert molding molds.

We have all facilities from design to testing trial.We have Hydraulic presses, Oven, oil boiler, Steam boiler, Vacuum pump, High pressure foam maker and so on.

After completing the mold, we can supply up to 100 pieces of PROTO products and mass production products.

We can manufacture molds with PROTO parts by merging with materials when developing the mold for new material, new method and low cost.

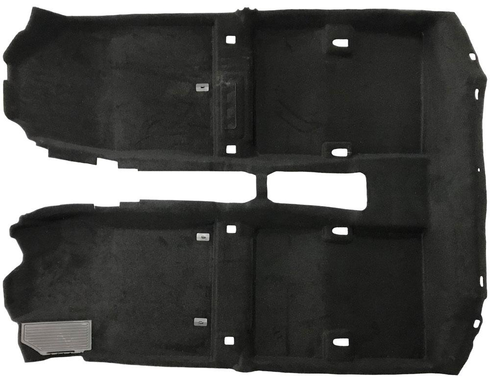

GMT(Glass Fiber Mat Reinforced Thermoplastics) mold is a mold process which developed to replace existing steel parts with GMT parts in order to reduce the price and light the weight of passenger cars and commercial vehicles.

The typical products are Back Beam of passenger car, Sheet Back of chair and Under Cover of engine.

Putting the material into the mold after heated to about 170 ℃. Then, it is compressed by press machine to make the shape.

As a merit, it is possible to insert glass mat or honeycomb sheet woven with resin such as P.P., so that high-rigidity functional parts can be produced at a low cost due to simplification of the process.

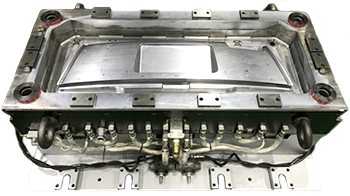

SMC(Sheet Molding Compound) mold, also can be called FRP mold, is mainly used for the automotive parts requiring high hardness such as bumper, step, back door of buses and trucks.

Putting the material into the mold after heated to about 180 ℃. Then, it is compressed by using a hydraulic press to make the shape.

It is mainly used for exterior parts of passenger cars and commercial vehicles. It is also widely used for electric vehicles to the purpose of weight lightening.

The surface of the product can be molded with glass, so it has been developed as an exterior part of the automobile.

DONG-A ENG Co., Ltd. is a mold manufacturer in the automotive interior and exterior parts since it has been established in 1992. We have improved the field of technology, material, product methods and design. We also have been involved in the development of ultrasonic cutting robotic system and the paint coating of automobile parts in the machinery department.

In addition, We operate our own factory in Czech Republic and a Maintenance Center in Thailand.

Finally, we would like to extend our sincere efforts to actualize customers’ benefit.